Corrosion prevention and surface protection effect on nonferrous metal surfaces

Anti-rust silicon resin coating

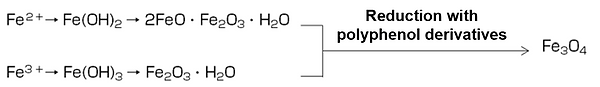

Converts progressive red rust on metal surfaces into stable black rust.

Rust conversion coating

Effective in preventing corrosion and protecting the surface of iron and zinc.

Rust-proof epoxy resin coating

Corrosion prevention and surface protection effect on nonferrous metal surfaces Anti-rust silicon resin coating

Produces a high-performance silicon resin film with high gloss and durability on nonferrous metal surfaces This film prevents nonferrous metal surfaces from coming into contact with moisture and dust.

In addition, it has excellent adhesion to metals that were previously considered difficult to adhere to.

It dries quickly both on the surface and after hardening, and is easy to work with.

Anti-rust Effect of

By coating MN-R, oxygen and moisture contained in the air do not chemically react with non-ferrous metal surfaces.

As a result, the customer's equipment can be protected over the long term from corrosive deterioration due to rust.

Renewal method without rust removal: Rust conversion agent

Since red rust progresses corrosion, this red rust is converted to black rust protected by strong bonding force and a hard coating.

Before

After

Renewal construction method that does not require rust removal is possible.

MN-RC prevents the progress of red rust and deteriorates over the long term simply by performing a simple surface treatment.

Old paint film and floating rust are removed by scraping the skin (rust other than floating rust does not require treatment)

Standards and cost of necessary rust treatment.

Produces an epoxy film to prevent corrosion on the surface of iron and zinc.

Prevents corrosion and oxidation and maintains the surface protection effect for a long time.

①Renewal construction method achieves low cost and

shortened construction period

②Long-term rust prevention and service life

③Safe and easy introduction

Evaluation test: saltwater spray test.

Corrosion behavior that occurs over a long period of time under natural conditions can be evaluated by compressing it in a short time.

Standard: JIS K 5600-7-1

Method: 5000 hours of continuous salt spray

Temperature 35°C/Concentration 5% NaCl (pH7) Specifications: Specimen rusted steel plate.

*Using steel sheets that have been exposed to the outdoors for 24 months and have rusted

Result: No abnormality (no rust, no peeling, no swelling)